Definition

The software is designed in such a way that it

automates order management by using previously entered

data about raw materials, semi - products, products,

users, tables, department or branch. It is possible

to get several different reports and to make analyses

related to the gathered data. This, in turn, increases

the efficiency and the service quality. The software

not only focuses on the automation of order collecting

process, but also it has inventory control or accounting

modules.

The software is fully compatible to the standard

Windows interface; and it has full security with

its structure organizing user permissions. It is

possible to predefine which parts of the system

would be used by each user. The software is compatible

with Windows 9X, NT, XP operating systems. Operations

are fast, since the application uses custom designed

inmemory database.

When the program is used via a handheld terminal

(usually a PocketPC):

The service attendants enter the orders to handheld

terminals. There is a wireless connection between

the handheld terminals and the server. The server

routes the order information to related clients

(usually a thin client or printer) in the kitchen.

Hence, the order that was entered by the attendants

can be seen realtime.

Since the order's follow up becomes easier, this

leads to a save of time in turn.

With its wireless infrastructure, this application

is especially appropriate for buildings with many

floors, wide area and garden.

Advantages of MODIS v.1.2.

- It is possible to follow the orders coming from

every handheld terminal in a different window on

the server.

- It is also possible to send message from the server

to handheld terminals or from handheld terminals

to other handheld terminals.

- You can give efficient service to more customers

with less number of personnel.

- If there is a client (thin client PC) in the

kitchen, the information that order is ready can

be sent to the related handheld terminal with table

and order number.

- The products can be grouped as food, drinks etc.

- It is possible to enter as many additional materials

as possible for the products by using semi-products

or raw materials ( e.g. sweet corn for the pizza).

- Some special notes can be added to check (well

done, spicy etc.).

- The handheld terminals are designed in such a

way that orders can be given, even when the handheld

terminals are not connected to the server. When

the connection is ready, the order is there to be

sent to the server. This makes possible to take

orders out of the restaurant.

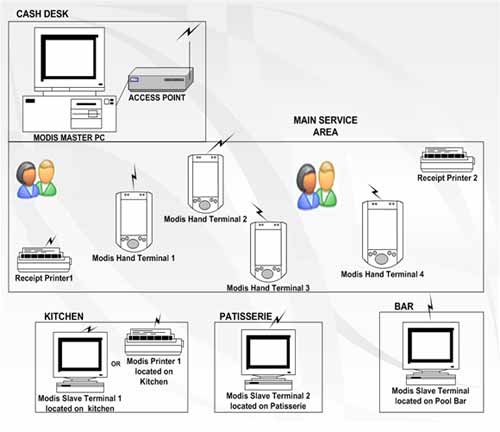

System Overview

Terms:

- Master PC (or System Server): Main service PC

that data from hand terminals are collected, reports

are taken and orders are directed to the related

production units ( via printers or Slave PC). There

is an access point connected through an ethernet

port.

- Slave PCs (or Displaying Units): Slave PCs are

displaying and feedback units that are located in

production units (PU - bar, patisserie, kitchen

etc.). The order information entered in hand terminals,

are displayed in related Slave PCs in bar, patisserie

or kitchen. Also, when the order is ready to serve,

a message can be send to hand terminals informing

the waitor that the order is ready.

A low profile PC is enough to be used as the Slave

PC.

- Hand Terminals: Pocket PCs via which orders can

be entered into the system. Pocket PCs include the

software of wireless ordering.

- Wireless hardware: The system can be installed

as totally wireless or as a mixture of wireless

and wired struructure. Generally, the infrastructure

is Standard Wi-Fi 802.11b/g Wireless Ethernet network.

PCI/USB Wi - Fi adapters can be used in Slave PCs,

hand terminals must have CF or SD slot or built

in Wi-Fi capability. Wi - Fi Print Servers that

are put on the parallel port, can be used in printers.

Wi - Fi 802. 11b Access Point should be used for

the Master PC. If required wireless repeaters (Access

Points) can be used to extend communication range

of the system.

General Structure:

|

|

Figure 1 - General Structure of MODIS System |

As it is seen in Figure - 1, the system is installed

on a standard ethernet network which has a totally

or partly wireless design.

Hand terminals that are built in wireless or became

wireless by Compact Flash (or SD) cards, are connected

to the Master PC through Access Points. Parallel

with this, PCs or printers used as displaying units

are connected to the Master PC through wireless

transmission adapters.

Modis Master software should become ready to transmission

and operation by using the related menus. With this

aim, the data about the system users, the information

about the user rights, the definitions of raw materials,

semi - products and products should be entered into

the system together with the information of table

numbers, section numbers etc.

Moreover, to establish transmission between channels,

the related port numbers and IP adresses should

also be defined.

Modis Master software opens a separate transmission

channel for each hand terminal and connects each

channel to a different window. This means that the

ordering data from each hand terminal are displayed

in a different window. In these windows, the current

situation of the orders are coded in different colors.

Open orders, changed orders or closed orders are

specified by a different color. Furthermore, by

putting the appropriate filters, it is possible

to display only the open orders.

As pre-defined at the beginning, the ordering data

coming from each hand terminal are displayed in

the related displaying unit. If a Slave PC is used

as the displaying unit, it is again possible to

display the orders' situations as coded by colors

together with sending the "order is ready" information

to hand terminals. Moreover, it is possible to send

an information message to hand terminals separately.

If a printer is used as the displaying unit (DU),

only the related part of the order is printed in

the related section's printer (such as steaks from

the kitchen printer, ice cream from the patisserie

printer etc.).

It is possible to enter and print orders and send

them to the related displaying units from Modis

Master software. Receipts or orders can be printed

both from the Master PC and from hand terminals.

Hand terminals are able to direct the receipt to

any one of the printers.

The software used by hand terminals has standard

Windows programs' interface. The user can enter,

cancel or change orders by using hand terminals.

Also, hand terminals can communicate with each other

(i.e. can send messages to them). When the connection

between the hand terminal and the Master PC is off,

the hand terminal is able to collect orders and

save them. After the connection is on, it is able

to send the saved orders to the system.

Precautions:

- The memory of Master PC should be 1 GB min.,

since all of the database operations are done in

Master PC's memory.

- Because of the same reason, Master PC should be

supported by a UPS with appropriate power.

- Extended batteries should be prefered in hand

terminals for an acceptable service time.

- Network infrastructure can be built as wired (10/100Base-T

Ethernet), wireless (Wi - Fi 802. 11b/g) or as a

hybrid structure.

- The operating system for Master and Slave PCs

should be Windows XP (Professional Edition).

- The operating system for hand terminals should

be at least Windows CE 3.0. (PocketPC 2002 or more)

- It is better to use Wi - Fi Print servers for

unit printers.

- All of the wireless hardware uses Wi-Fi 802.11b/g

infrastructure. With this aim, Master PC is connected

to an Access Point. Slave PCs have wireless adapters.

Printers (whether receipt or production unit printers)

include wireless print servers. In the same way,

hand terminals have wireless adapters.

- If the security specifications of wireless hardware

are prefered to be included, it is advised to use

802. 11g standard for a better system performance.

- The number and quality of wireless hardware must

be specified after the physical environment analysis.

It is very important to configure the hardware according

to the real working environment. Wireless repeaters

can be used according to the distance between the

hardware.

<<back

© Copyright (c) 2000-2005

Sydma CONTROL All rights reserved

|